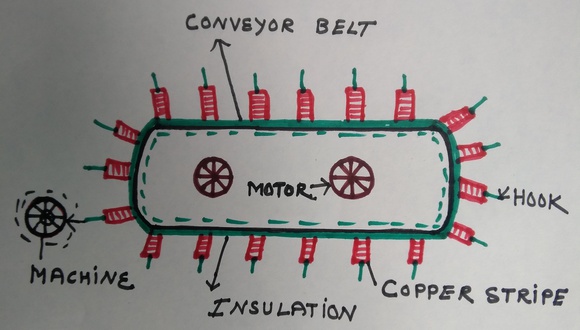

Copper stripe based cooling system

The presented Idea is based on Heat exchange principle.As per sketch there will be a conveyor belt system and some copper stripes will be connected with this belt.Each copper strip will have a moveable hook.The conveyor belt will move with a motor.Each copper strip will be separated with each other and with conveyor belt with the help of Insulation (wooden insulation).Each copper strip will be connected with the machine for 15 to 20 seconds to absorb the heat and after that this copper strip will be removed and next copper strip will be ready to absorb the heat.The removed strip will be cooled down after some time and will be ready to couple with the machine again.In this way each copper stripe will work one by one to absorb the heat to cool the machine and each strip will get cool down due to convection .

What I thought is that if I use a continuous water jet to cool the motor then the motor will remain cool so if I use the copper stripes then the same effect will be occured.It will work in this way that temperature will be not increased of machine if I couple the device with the machine?