Finalist Highlight: Banking Today's Materials to Power the Future

The efficient recycling of lithium-ion batteries will rely on strong market infrastructure. Clarios' existing lead-acid battery collection network provides the necessary backbone to ensure this recycling process is sustainable and enduring. The "Powering the Future" team assembled by Clarios includes industry partners and experts to implement safe handling of spent and discarded lithium-ion batteries.

"Clarios is uniquely positioned to be a player in the lithium recycling economy," said Power the Future team captain Michael Sendelbach. "Our solution highlights how our commitment to sustainable life-cycle management can provide a scalable answer for end-of-life and second-life battery solutions."

Clarios plans to implement a closed-loop economy through five distinct stages: batter collection, sorting and diagnoses, separation and packaging, transportation, and recycling. At each step in this process, the team has partnered with industry experts to provide state-of-the-art solutions, including Global Battery Solutions, Admiral Instruments, Environmental Restoration, and more. By coordinating between organizations, Clarios can adapt its process to distinct subgroups of end-of-life lithium-ion batteries.

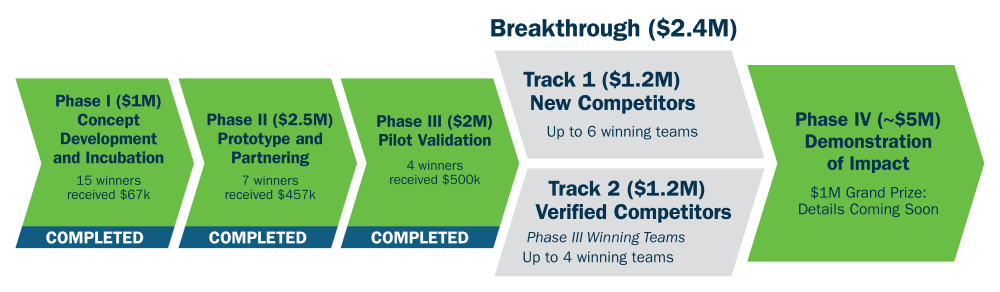

The Power the Future solution implemented a successful trial run in Phase II of the Lithium-Ion Battery Recycling Prize. In Phase III, the team plans to incorporate hardware and packaging solutions for a pilot-scale demonstration. In addition, Clarios will be collaborating with Voucher Service Providers from the American-Made Network to expand cost modeling tools to guide future implementation.

To learn more about Powering the Future, contact or .