Innovation is business as usual for the students in Dr. Moble Benedict’s Advanced Vertical Flight Laboratory at Texas A&M University, but when the lab members first heard about the GoFly Prize, they knew it would be a challenge unlike anything they’ve ever experienced. Still, Benedict and his students formed a team, Texas A&M Harmony, and started brainstorming.

The team spent over a month mulling over some of the competition’s most challenging requirements. From building a device small enough to fit in a garage to ensuring that the noise it generates does not exceed 87 decibels, there were numerous elements to consider, from the overall vehicle design to the propulsion system.

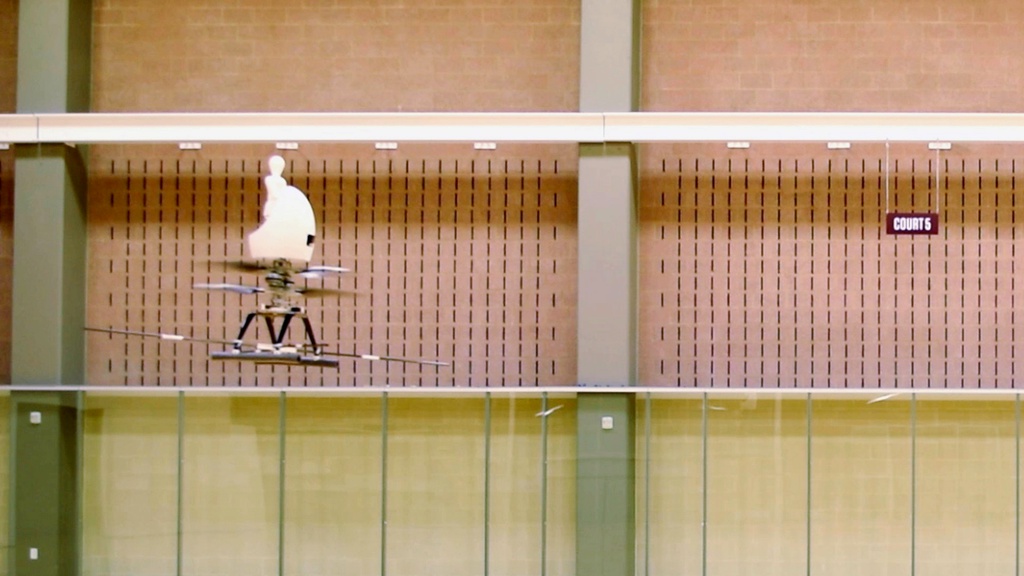

Armed with a concept, the team embarked on Phase II of the GoFly Prize facing an even more difficult task: building the device. Through simulations and real flights, team Texas A&M Harmony tested 200-300 thousand design iterations of their device prototype, the Aria, a high-TRL (technology readiness level) compact rotorcraft. Now, as they continue to Phase III, this group of students is pushing the boundaries of personal aviation, inspired by both transportation’s past and its future.

Finding Inspiration Everywhere

Though Texas A&M Harmony is made up of students specializing in a variety of aviation and aerospace disciplines, the team became aware early on that to thrive in the GoFly Prize, they’d have to get outside their comfort zones and draw inspiration from their surroundings as well as from historic innovations. For Benedict, the invention of the automobile is a useful reference for envisioning personal aviation.

“Before automobiles, there were horses and carriages, or trolleys, and people were fairly limited in how far they could travel and how quickly. Then, when the automobile came about, everything changed,” Benedict says. “Suddenly people were able to drive further and get to their destinations much faster. That human mobility and freedom to move around made a big impact on where people lived, worked, and traveled.” Over time, Benedict predicts, personal flyers will be just as much an extension of their owners as cars have become.

But cars today aren’t all about getting from point A to point B—from sunroofs to tailgates, features in today’s vehicles are designed to amplify the experience of driving and car ownership. For personal flyers, experience matters too. “I was recently on a virtual reality ride at Disney where there’s this feeling of flying through the air, totally uninhibited by anything,” Benedict recalls. “And I thought, ‘That’s the feeling that this personal flyer should be creating.’ Of course, safety is a priority, and it needs to be functional, but creating that sense of freeing human flight has been our guiding force.”

Bigger and Quieter Goals

Despite their bold ambitions, Texas A&M Harmony has learned that combining function with an extraordinary flight experience is no easy feat. The team systematically designed the rotors to minimize noise and maximize efficiency through aerodynamic models, but they still had to test their claims. Over a span of a month and a half, they built a one-third scale model of the Aria to validate their different predictions, and they tested the model’s aerodynamics and acoustic performance using rotorcraft industry standards. The results affirmed their predictions and have given the team more knowledge and confidence for Phase III.

At the same time, the team is working hard to make sure that other pieces of the puzzle are ready for Phase III as well. “We’re pushing the boundaries of an electric motor because helicopters need a lot of power to simply hover,” Saemi explains.

To make sure they were getting it right, the team conducted dynamometer tests of the motor drive system at a commercial testing facility. The dynamometer simulated the loads generated by the rotor, which is specially-built from composite materials for high strength-to-weight performance. The team also evaluated different battery chemistry to find the one that would give them the most energy per mass unit. “Ultimately, the cell we selected for our prototype is one that’s on the cutting edge of its field, built especially for the aviation community,” according to Saemi.

With Phase I and II behind them, Texas A&M Harmony is ready to take the Aria prototype to the next level and build a full scale device. “Everyone on the team wants the same thing. We want to get to the Fly-Off and see this device in the air, but we still have a lot of work to do,” Benedict says. Still, the team is up to the challenge. Back when Phase II was wrapping up, the team did everything in their power to complete their submission on time—even though it meant some long nights.

“No one went home for Christmas. We knew the end of Phase II was near and we just had to get this thing finished,” Benedict recalls. “But the team has never lost that positive energy, always focused on the end goal as they developed scale models, conducted flight testing and worked in the lab all through break. With that dedication, we know we’ll make it to the end.”